The Henschel Tiger Factory Page 3

|

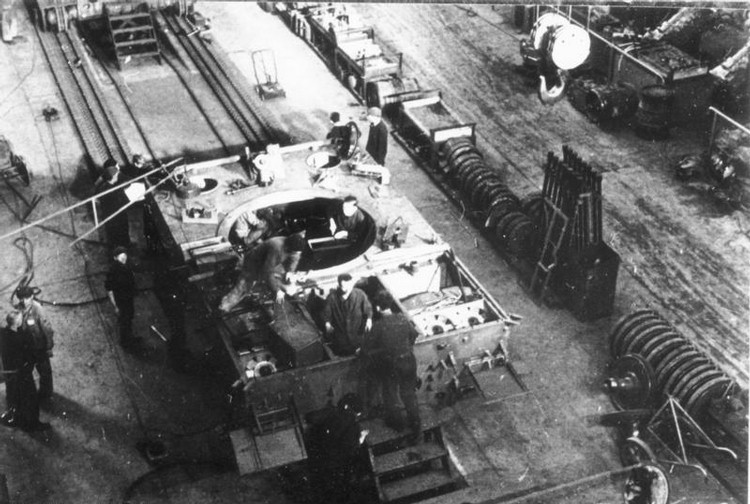

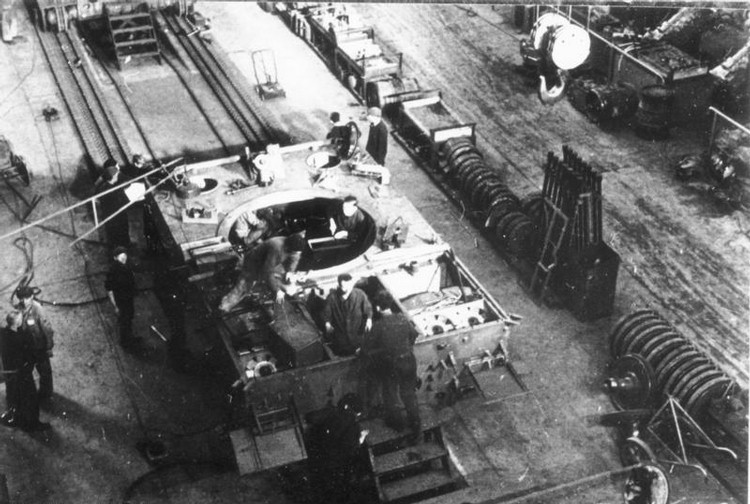

A great deal of internal work is done prior to track fitting.

Notice the tracks laid out in front of this Tiger.

|

| |

|

| The hull is now readied for installation of the tracks.

|

| |

|

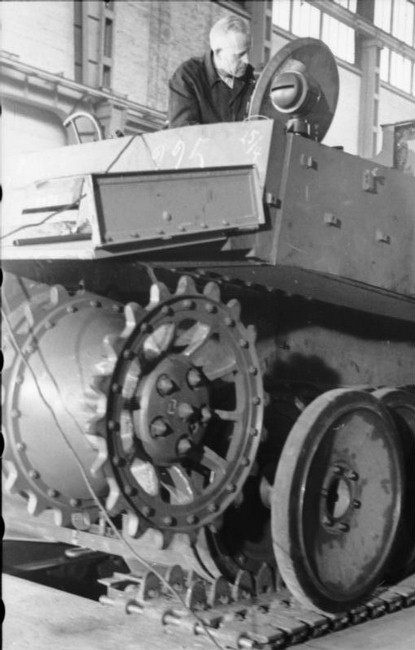

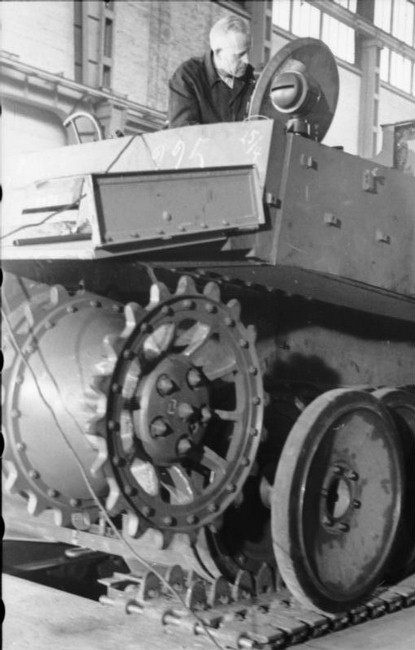

| Workers use a steel cable wrapped around the drive sprocket to pull the track into place. This is the same method that will be used in the field to install tracks.

|

| |

|

A Henschel employee works in the drivers hatch area as

the tracks are being fitted.

|

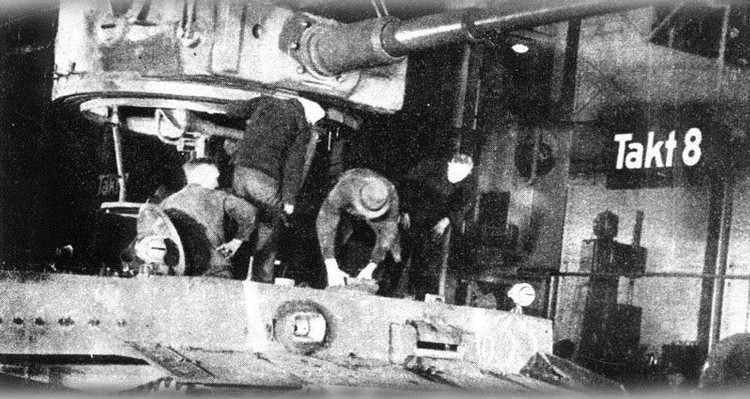

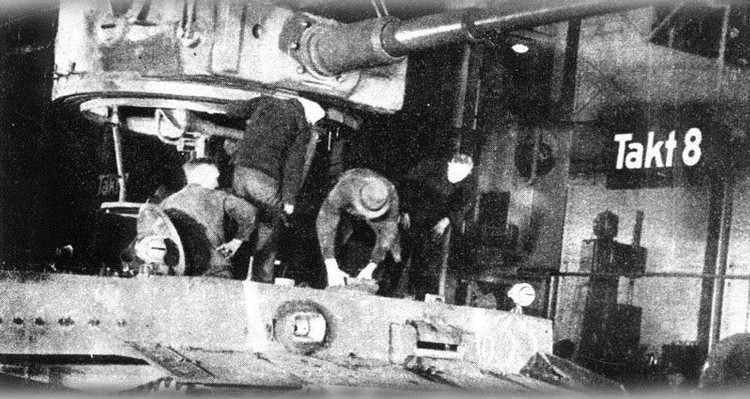

At this point Step 6 began and the Tiger was painted, but only the lower hull and sides. Then it was on to Step 7 in which the Tiger was taken on a test drive. Any problems during the automotive tests were noted and repaired before the Tiger went on to Step 8. In this step the final equipment fitting took place the most notable of which was the attachment of the turret to the hull.

|

| The biggest part of TAKT 8 was the installation of the turret.

|

| |

|

| The turret basket is shown clearly as the turret is lowered down onto the hull by the overhead crane. The outer roadwheels are missing since this Tiger is wearing the narrow transport tracks.

|

| |

|

| Workers watch carefully as the turret is almost in place.

|

| |

|

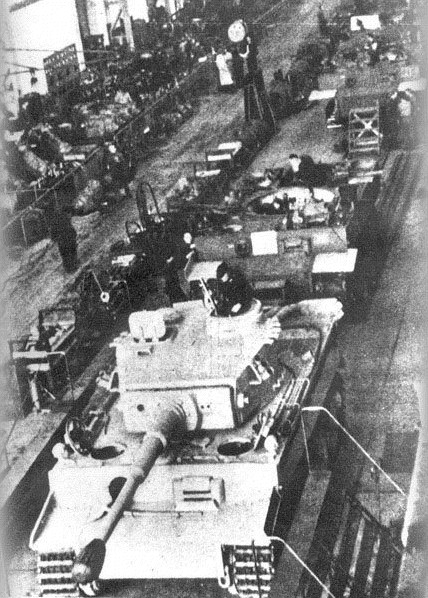

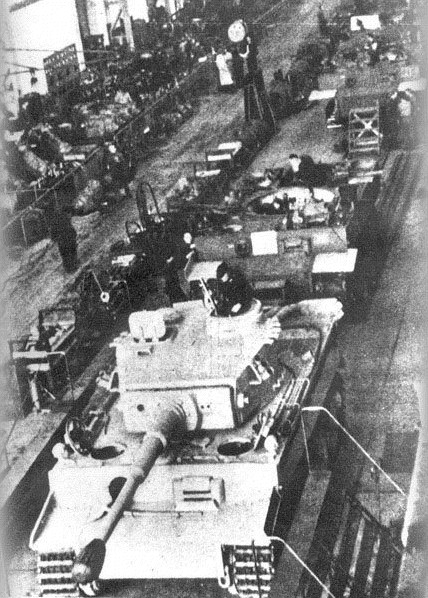

| This Tiger is almost complete as evidenced by the finishing touches such as the MG and muzzle brake covers and the shovel in place on the front hull. Overhead an engine is being hoisted to a Tiger further down the line.

|

| |

|

Another Tiger is close to completion. Notice the stairs to the side of

the Tiger used to make access easier for the assembly line workers.

|

Step 9 consisted of the final painting of the Tiger and later in the war the application of Zimmerit. Henschel did not apply camouflage paint jobs at the factory. At this point the completed Tiger was ready for delivery.

|

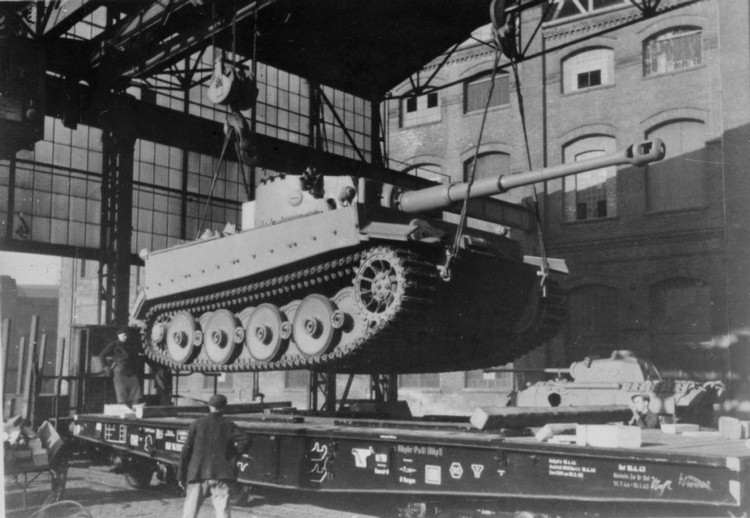

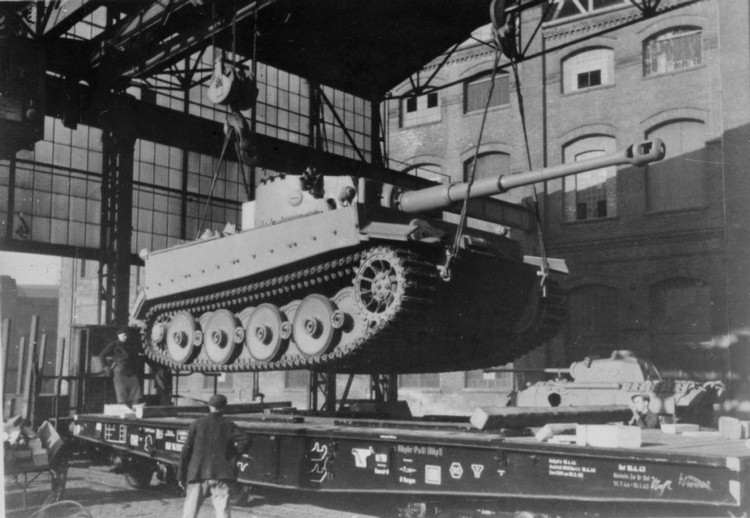

| A completed Tiger is loaded onto a special railcar. Note that the fender skirts are not installed at the factory as they would cause the tank to be too wide for rail transport. Also notice the completed Panther in the background.

|

During the war the city of Kassel was bombed some 40 times by the Allies. This disrupted Tiger production, most notably in late 1943 when during the night of October 22/23 the RAF dropped 1800 tons of bombs causing severe damage at the Henschel facilities as well as killing or injuring a good portion of its workforce. Yet production continued right up until the end. The U.S. Third Army began the battle to capture Kassel on April 1, 1945 and, as they approached, the Henschel factory completed work on 13 Tiger II tanks which were handed directly over to two companies of schwere Panzer-Abteilung 510 and 511. Three days later at 1200 hours on April 4, 1945 the city was surrendered and Henschel Tiger production was forever ended.