|

| Stacks of roadwheels await finishing in the roadwheel assembly area next to a finished Tiger coming off the line. |

|

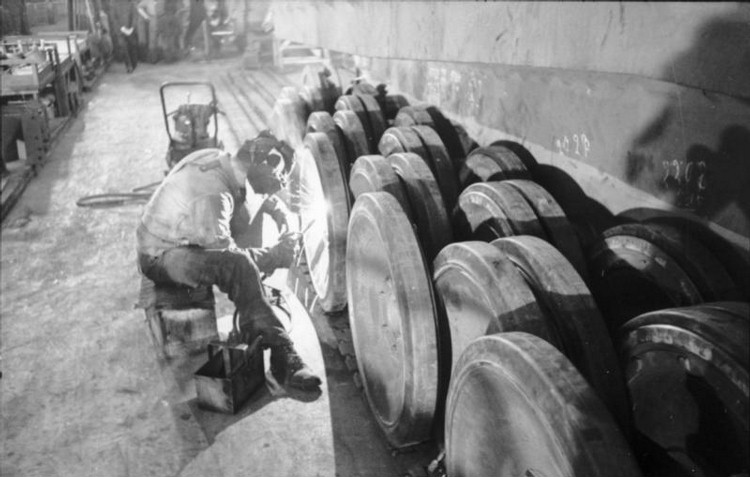

| Workers assemble roadwheels in preparation for installation on the Tiger. |

|

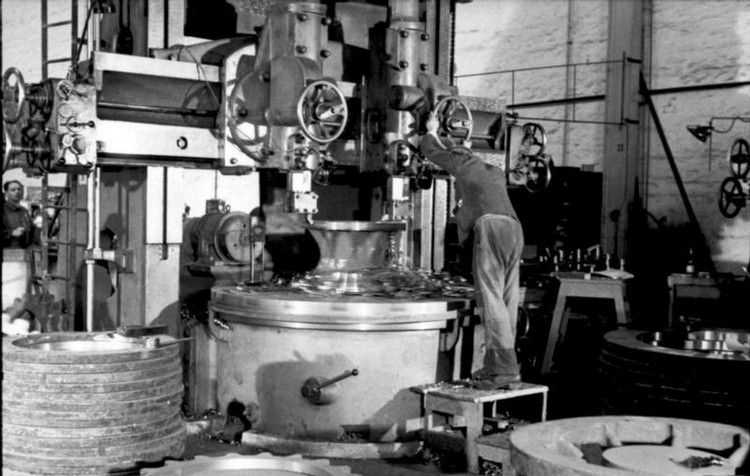

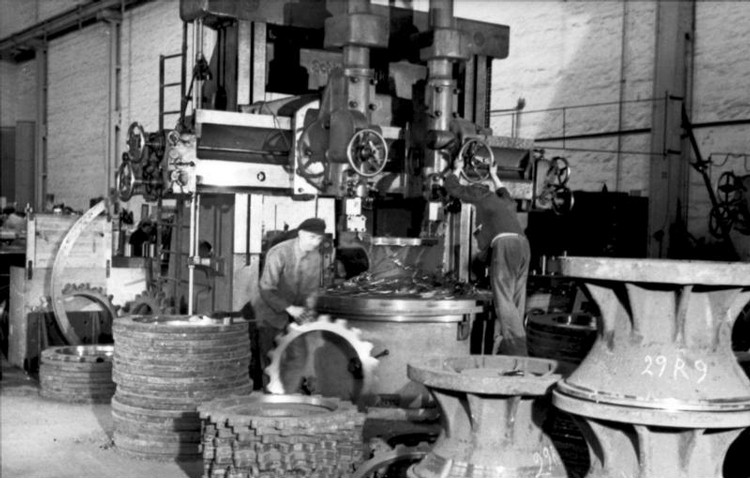

| A worker stands on a wooden platform to perform finish machining on a raw drive sprocket casting. |

|

| Stacks of raw unfinished ring gears wait to have their teeth cut into them as a worker rolls a completed ring gear to the adjacent stack. Note the rough surface of the drive sprockets in the foreground. |

|

| Here a worker uses another colossal piece of equipment to machine one of the Tiger's suspension arms. |

|

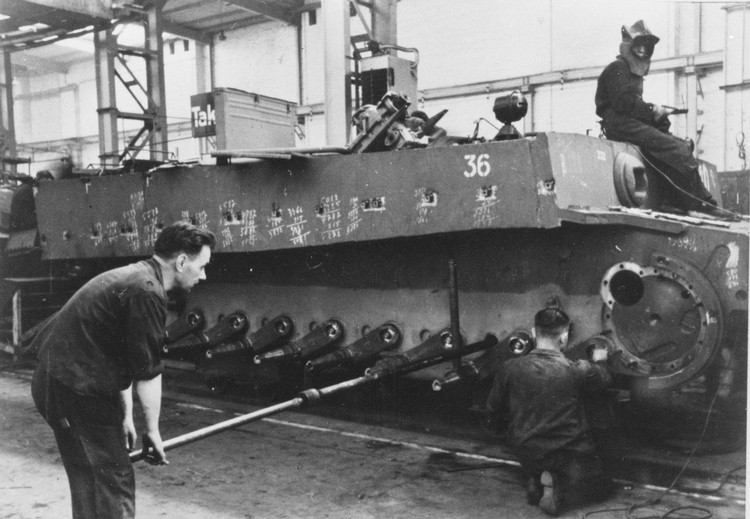

| A worker performs welding on the front of the Tiger's hull as suspension installation begins. Note the steel wheeled bogey under the hull that moves the Tiger along the rails in the factory floor. |

|

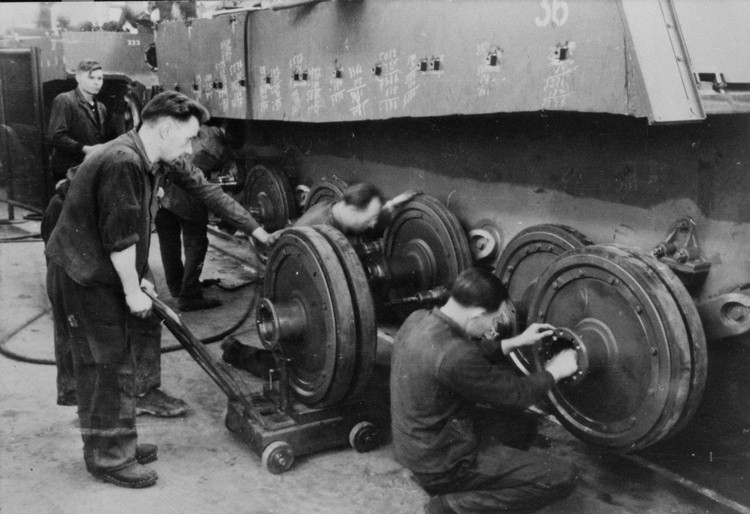

| A rear idler arm is installed using a special hydraulic trolley. Note the measurements written on the hull side and the markings for the fender skirt attachment points, which have not yet been installed. |

|

| A worker installs one of the Tiger's long torsion bars. Notice the length of the tool he is using which will give him enough leverage to move the other end of the bar once it is inserted all the way into the hull. At this point the fender skirt attachment points have been welded on, probably by the welder resting on the top of the tank. |

|

| As suspension work continues, a fresh Maybach HL 210 P45 engine is brought in by the overhead crane. |

|

| The Maybach HL 210 engine is carefully guided into the tight confines of the Tiger's engine compartment. |

|

| Another special trolley is used to guide a roadwheel into place. |

|

| Final welding is performed on these early style roadwheels. |